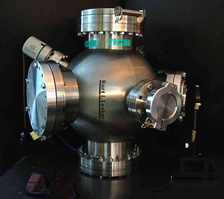

Among the physical deposition methods of preparation of thin layers (called physical vapour deposition - PVD) in our department we use a PLVD (pulsed laser vapour deposition) technique based on the use of ablation of the material under influence of pulsed laser beam. This technique is particularly useful for research purposes, because of possible selection and control of the experimental conditions and process parameters in a wide range. Selectable process parameters are: substrate temperature, base pressure, the intensity of the vapour stream (system geometry, the distance the substrate from vapour source, the rate of evaporation), the energy of the vapour stream (depending on the density of pulse energy, laser wavelength and pulse rate), the type of material used pair production (solid or powder/nanopowder pressed), and type and pressure of buffer gas.

more »

Selected substrates (e.g. stone, paper) are investigated by means of spectroscopic and surface inspection techniques (LIPS, LIF, DRIFT, colour-metrics, Raman, XRF, and AFM, SEM, TEM) for characterization of museum objects and historical artworks. Results are collected and databases accessible for the international conservator's community are developed...

more »

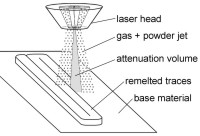

The subject carried out on national and international level cover experimental and theoretical studies on multilayers and protective coatings prepared by laser remelting of metal alloys and composite powders for applications under extreme operating conditions (e.g. steam turbine blades, high-load bearings etc). Phenomena associated with the coating preparation and its heat treatment (thermal tensions, micro-cracks) and these corresponding to operation and stresses observed for coated machine elements (corrosion, wear) are investigated by means of numerical models based on finite element method. Coatings are prepared at the IF-FM.

» Experimental workstation for deposition of protective coatings and fast prototyping by laser cladding.

more »