High quality coatings and multi-functional structure

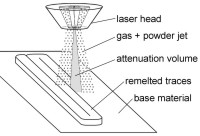

The subject carried out on national and international level cover experimental and theoretical studies on multilayers and protective coatings prepared by laser remelting of metal alloys and composite powders for applications under extreme operating conditions (e.g. steam turbine blades, high-load bearings etc). Phenomena associated with the coating preparation and its heat treatment (thermal tensions, micro-cracks) and these corresponding to operation and stresses observed for coated machine elements (corrosion, wear) are investigated by means of numerical models based on finite element method. Coatings are prepared at the IF-FM - Experimental workstation for deposition of protective coatings and fast prototyping by laser cladding.

Their properties are examined by optical and scanning microscopes (SEM), by means of the surface, elemental, and spectroscopic analysis methods (AFM, EDS) and also the metallographic, corrosion and wear resistance tests are performed.