The Institute of Fluid Flow Machinery in colaboration with ESLT company from Warsaw developed robotized system for cutting plastics and metals. This project was develped with the project of NCRD (The National Centre for Research and Development) nbr INNOTECH-K2/IN2/87/182010/NCBR/13. The system allows cutting of the materials, such as: PP (Polipropylen), PE (Polietylen), ABS (poli(akrylonitryl-co-butadien-co-styren)) polymers. They are widely used in automotive industry, Household appliances, sport equipement, furniture, photography and in toys manufacturing. The system includes many innovatiove solution, such as:

-

innovative laser beam quide system along industrial robot arm

-

ability to use with popular industry robots (e.g. welding robots)

-

5 exchengable robot grippers with tools

-

4 different lasers can works seperately or two can work together

-

the system allow to cut, weld, mark on 3D surface in the area of 2m x 2m x 1m

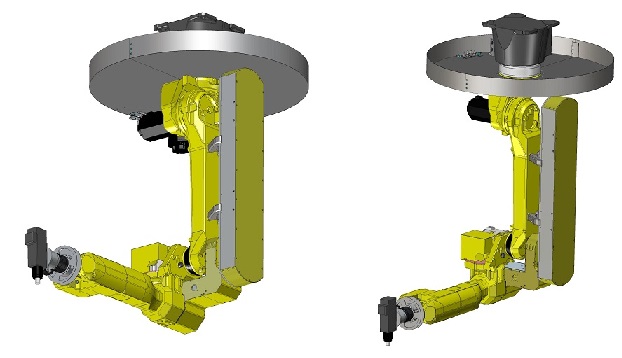

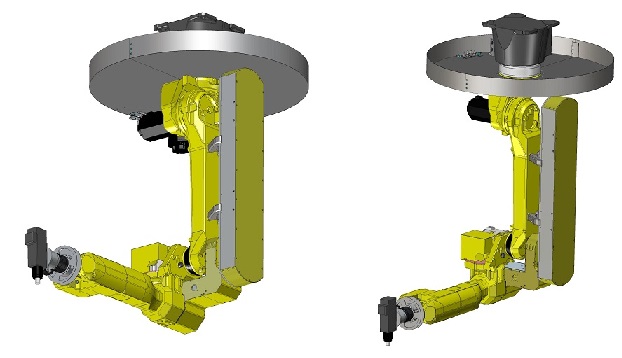

Fig. 1. Fanuc robot arm (m20iA) equiped with beam guidance system for CO2 laser.

There are 4 lasers available now in the system:

-

CO2 laser from Coherent (Diamond-1000) with average power 1kW, pulse repetition 200 kHz and pulse power 2.5kW (RF type)

-

diode laser from Apollo Instruments (S500-808-6) with average power 500W, wavelength 808 nm, coupled to the fiber with 0,6 mm core diameter

-

Nd:YAG Q-Switch laser combinde with scan head for the wavelength of 532 nm (from ESLT)

-

Bd:Yrb fiber laser (from IPG)

To take advantage of our offer, please contact Dr Robert Barbucha: email: brobert@imp.gda.pl, tel. 506 310 086

We use RoboDK for simulation and offline programming of industrial robots (RoboDK website)